Thorens TD125Mk2 repairs

My stereo and other stuff

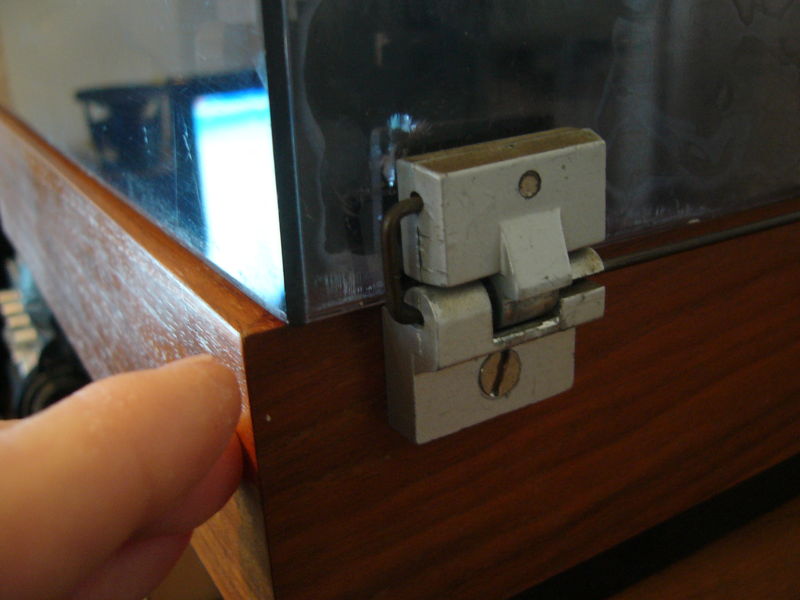

Thorens TD125Mk2 hinge ass'y.

TD 125Mk2 Strobe repair and suspension tuning

Thorens TD125Mk2 torsion spring hinge ass'y.

Photos of the Thorens TD125mk2 torsion spring hinge system. What a bitch to reassemble after it unexpectedly flies apart on you, especially since I never paid attention to how it was assembled in the first place!